VACUUM BAGGING TECHNIQUES

What is vacuum bagging?

Vacuum bagging (or vacuum bag laminating) is a clamping method that uses atmospheric pressure to hold the adhesive or resin-coated components of a lamination in place until the adhesive cures. (When discussing composites, “resin” generally refers to the resin system— mixed or cured resin and hardener—rather than unmixed epoxy resin.)

Modern room-temperature-cure adhesives have helped to make vacuum bag laminating techniques available to the average builder by eliminating the need for much of the sophisticated and expensive equipment required for laminating in the past. The effectiveness of vacuum bagging permits the laminating of a wide range of materials from traditional wood veneers to synthetic fibers and core materials.

SILICONE FOR VACUUM BAG

Silicones for Producing Reusable Vacuum Bags

- Our silicone rubber is a brushable platinum cure silicone developed especially for making high performance, reusable vacuum bag. It is easy to mix and apply. Rubber can be applied with a brush or spatula to vertical surfaces without sagging.

- CHEMZEST offers a series of addition cure silicone elastomers for the manufacture of reusable vacuum bags for resin infusion. These silicones formulated as a sprayable material allowing for exceptionally low cost composite manufacture using resin infusion technology.

- Our silicone solutions enable composite manufacturers to decrease production times, achieve consistent part production and reduce material waste. In addition, the closed mold process enables a much safer working environment since VOC emissions are reduced.

General Attribute

- 1:1 mix ratio

- Easy to apply using fully automated mixing and spray equipment

- Fast curing heat accelerated RTV

- High tear and tensile strength for repeated uses of the bag

- Low viscosity

Applications

- Automotive parts such as bumpers and windscreens

- Aerospace components

- Marine & RV components

- Laminating

- Composite part building

- Molded composites

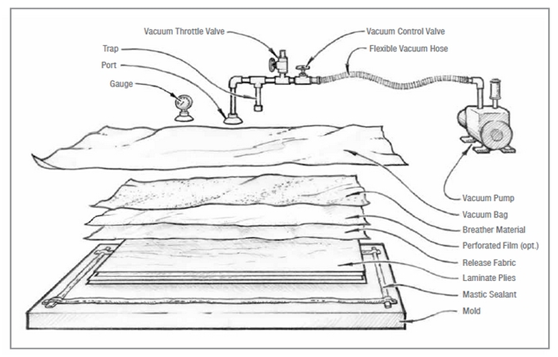

How it works?

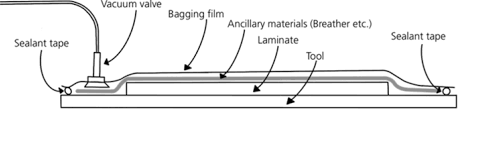

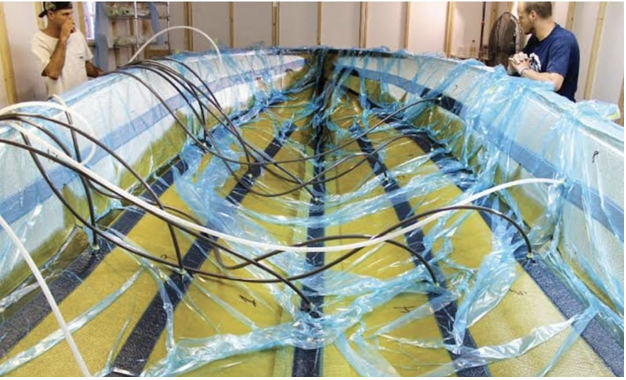

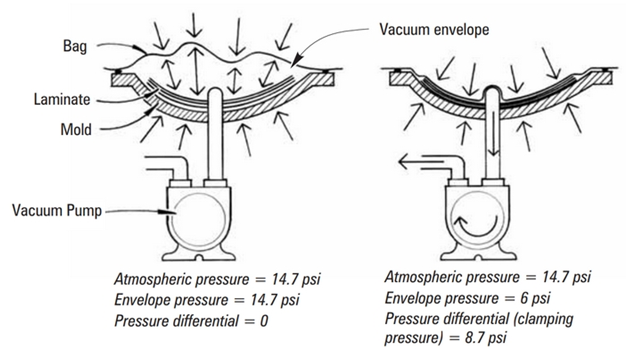

- Vacuum bagging uses atmospheric pressure as a clamp to hold laminate plies together. The laminate is sealed within an airtight envelope.

- The envelope may be an airtight mold on one side and an airtight bag on the other. When the bag is sealed to the mold, pressure on the outside and inside of this envelope is equal to atmospheric pressure: approximately 29 inches of mercury (Hg), or 14.7 psi.

- As a vacuum pump evacuates air from the inside of the envelope, air pressure inside of the envelope is reduced while air pressure outside of the envelope remains at 14.7 psi. Atmospheric pressure forces the sides of the envelope and everything within the envelope together, putting equal and even pressure over the surface of the envelope.

- The pressure differential between the inside and outside of the envelope determines the amount of clamping force on the laminate. Theoretically, the maximum possible pressure that can be exerted on the laminate, if it were possible to achieve a perfect vacuum and remove all of the air from the envelope, is one atmosphere, or 14.7 psi.

Vacuum bagging equipment

The vacuum bagging system consists of the airtight clamping envelope and a method for removing air from the envelope until the epoxy adhesive cures. This section discusses the components of this system , which include both specialized equipment and commonly available materials.

Vacuum Bagging Materials

- Release Fabric

- Perforated Film

- Breather material

- Vacuum bag

- Mastic sealant

- The plumbing system

- Mold release

Our product benefits

- High mechanical characteristics

- High dimensional stability

- Self bonding properties ( a second layer can be cast within 24hrs after casting the first layer)

- Good chemical resistance against polyester,vinylester

- Perfect surfaces in both side of the mold

- Translucent product in order to recognize the filling of the resin

MAJOR APPLICATIONS