FLEXON-POLYURETHANE RUBBER

- FLEXON Liquid Polyurethane Rubber is room temperature cure, mid-range to firm hardness (Shore A40-A80) with high performance.

- Most concrete mixes and polyurethane resins require a suitable release agent. Vacuum degassing of mixed material using a vacuum pump and chamber to remove entrapped air is recommended.

FEATURES

- High hardness A40-A80, which silicone rubber unable to reach.

- Super strength, 3 times stronger than silicone rubber, high abrasion resistant, super tough rubbers.

- Reproduces fine details and textures.

- Long lasting, Economical ideal for high volume casting applications.

- All rubber can be demolded after 5-8 hrs.

Typical Uses & Applications

Primarily used for high production of concrete casting, forming, texture mats.

To make

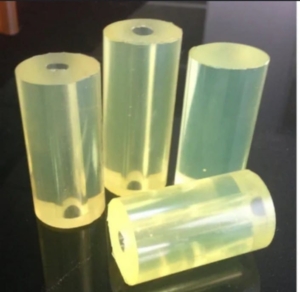

- Rubber Rollers

- Spare Parts

- Impact Protective Parts

- Concrete Stamps

| Physical Properties | PUR 40 | PUR 50 | PUR 70 | PUR 80 |

| Hardness (Shore °A/°D) | 40°A | 50°A | 70°A | 80°A |

| Appearance | Light Green | Light Green | Light Green | Light Green |

| Mixing Proportion (wt %) | 100:40 | 100:50 | 120:100 | 100:100 |

| Operating Time (Min @25°C) | 10 | 10 | 10 | 10 |

| Curing Time (Hrs @25°C) | 4-8 | 4-8 | 4-8 | 4-8 |

| Viscosity (cPs @25°C) | 1500-2500 | 1500-2500 | 1500-2500 | 1500-2500 |

STIFON-POLYURETHANE RESIN

STIFON Liquid Polyurethane Cast Resin is a 2 Part system consisting of a Polyol resin and a isocyanate hardener, which after mixing causes a chemical reaction and forms a hard solid surface.

FEATURES

- High reactivity and low viscosity

- Two component rigid Polyurethane Resin

- High hardness (90 shore A-75, Shore D)

- Good Physical and mechanical properties

- Can used with open casting, rotational casting and Vacuum Casting

TYPICAL USES & APPLICATIONS

- Casting Prototypes

- Architectural reproductions

- Duplicate masters production parts figures

- Molded bars

- Plugs caps

- Toy parts

- Casting,Frames,Thumbnails vehicles parts

| Physical Properties | PUR 90 | PUR D75 |

| Hardness (Shore °A/°D) | 90°A | 75°D |

| Appearance | Light Green | Light White |

| Mixing Proportion (wt%) | 70:100 | 100:75 |

| Operating Time (Min @25°C) | 10 | 2 |

| Curing Time (Hrs@25°C | 4-8 | 2 |

| Viscosity (cPs @25°C | 1500-2500 | 1500-2500 |