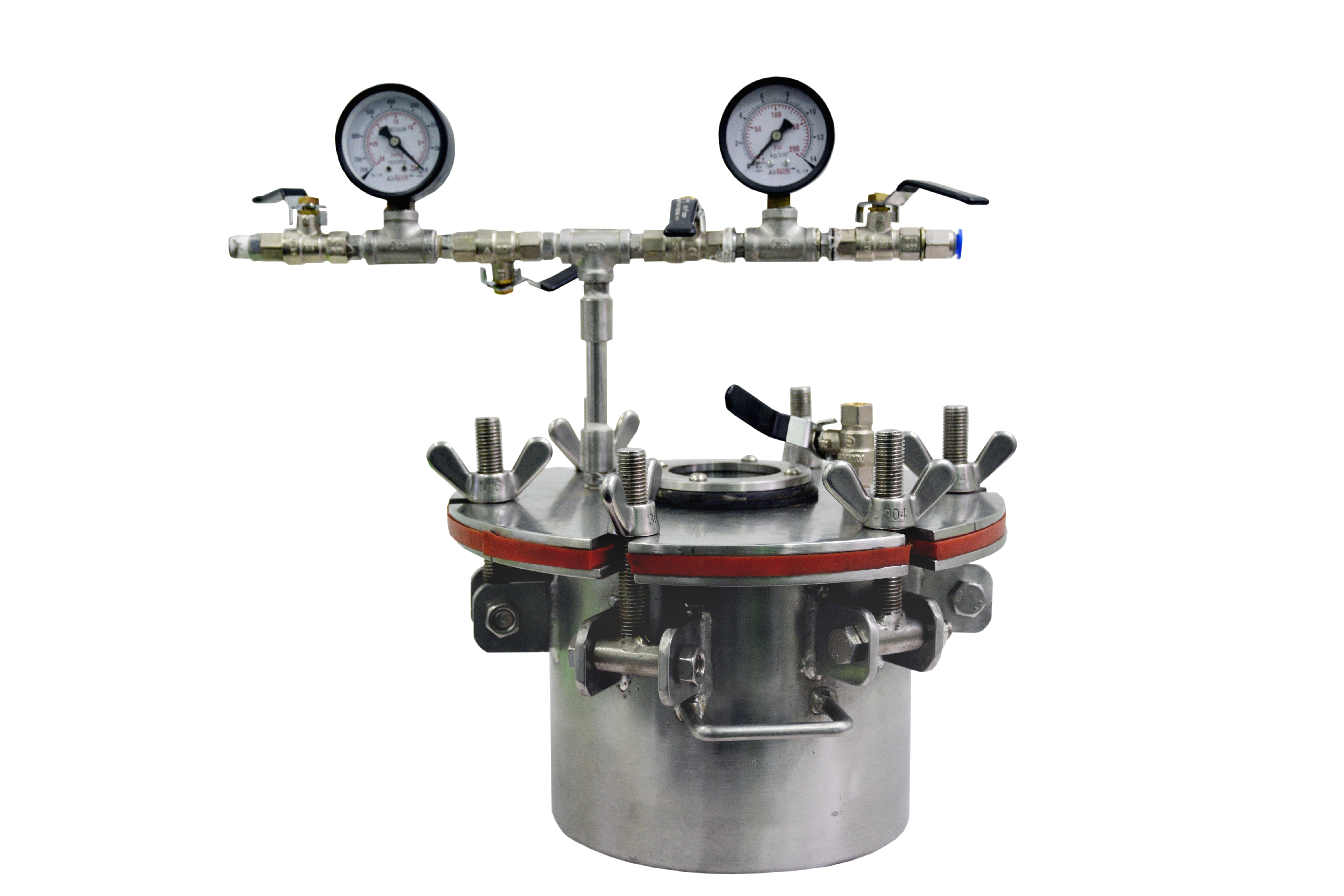

A pressure pot is required for bubble-free and air-trap-free resin castings. This is especially critical in creating clear resin castings as trapped air can make the foggy appearance of a crystal clear casting. The CHEMZEST Pressure Pots are designed for use in applying pressure to force air out of resin and to force resin into thin sections of a mold. This eliminates air bubbles and air traps in the cured castings.

Casting under pressure is the best way to make high quality resin castings. This is especially true with difficult recesses and complex molds. Pressure casting compress air to sizes undetected by the human, creating a virtually bubble less casting.Simply cast your part in your mold and then insert your mold into the pressure pot. Secure the lid tightly, and then turn on your air supply tofill the pot to 40-50 PSI. (DO NOT EXCEED 50 PSI). Leave the pressure pot on until the casting has cured. Then remove the air source and release the air from the pot. Unfasten the lid and remove your mold from the pot. Demold your void free casting.

You will want to make certain you do not pressure cast soft rubbers as the air bubbles will return once exposed to normal air pressure. You must use your vacuum chamber to remove all air from the mold rubber to avoid having the mold collapse in areas of your mold that have air trapped under the surface. You will have the appearance of warts on the surface of the finished result if you do not.

Casting Methods

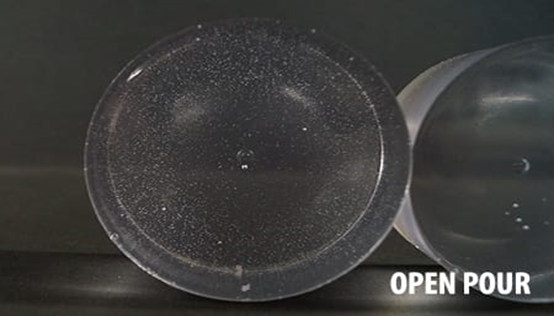

- Open Pour

- Vacuum Degassing

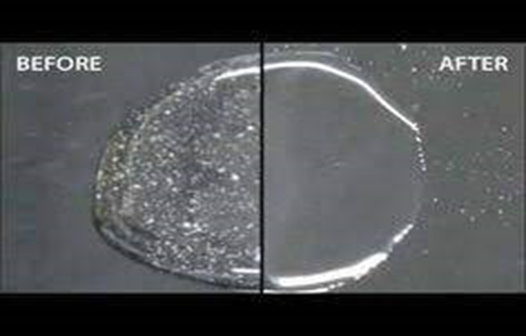

- Pressure Casting

The open pour method results in hundreds of tiny air bubbles which are quite obvious in the final casting.

Vacuum Degassing is most suitable for removing bubbles from the mold making materials like Silicone/Polyurethane.

The resin cast under pressure resulted in the casting with the least air bubbles. When the resin is removed from the chamber, it appears bubble-free.

The recommended casting method for bubble-free, clear parts is pressure casting.

- The Pressure Pot provides you with a crystal clear bubble-free as well as an air trap-free resin casting.

- A simple and very easy solution for degassing your resin casting

- If you have a variety of smaller items to degas, then this method is an affordable way to do this.