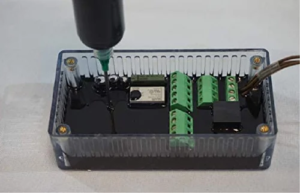

POTTING EPOXY RESIN (BLACK)

- It is two-part potting epoxy system with Glossy, low viscosity and circuit assemblies in a protective block to protect from moisture, water and Dust pollution.

- It is a range of high-performance user-friendly epoxy resins.

FEATURES & BENEFITS

- Very less shrinkage

- Excellent moisture, air & Dusta protection barrier, stable in acidic pH solutions

- Excellent flow properties (low viscosity) with efficient substrate wetting.

- Unique mechanical properties

APPLICATION

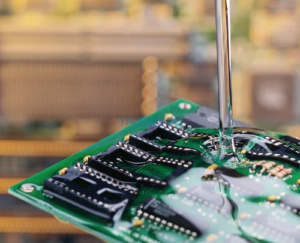

- Potting epoxy resin is used to encapsulate printed circuit assemblies in a protective block.

- The cured epoxy improves reliability, operational range, and lengthens the life of electrical and electronic parts.

- Its primary applications involve protecting electronic devices from water, moisture, dust and chemically aggressive environments in the automobile, marine, aerospace, aviation, communication, instrumentation, and industrial control equipment.

TECHNICAL GUIDELINES FOR USING

- Measure the Part A ( Resin ) and the Part B ( Hardener ) in two separate containers.

- Transfer Part A into the suitable container

- Start gentle stirring

- After stirring the Part A, transfer Part B to it.

- Continue the gentle stirring & Reaction to progress.

- Take care not to get air trapped within mixture

- The Mixed epoxy resin should be applied or poured within 5-10 min Time.

- For design applications, Degassing may be required to remove the Air bubbles from the texture.

- Upon curing remove the material from moulds.

STORAGE & PRE-MIXING

- The two components (Resin & hardener) should be stored in separate at all times prior to use.

- Store in cool, Dry & Away from Sun Light.

- Warm Temperature should be avoided in storage area , Warm temperature reduce the shelf life.

- The handling equipment & the storage area should be free from chemical residue, Foreign matters.

SHELF LIFE

Twelve (12) months from date of shipment when stored at 25oC in the original sealed packages.

EPX-205-FLEXIBLE EPOXY RESIN

It is two-part flexible epoxy system with Glossy, low viscosity. It is a range of high-performance user-friendly epoxy resins.

FEATURES & BENEFITS

- Excellent Waterproofing and Encapsulation

- Can be Pigmented using suitable pigments

- Very less shrinkage

- Excellent moisture protection barrier, stable in acidic pH solutions

- Excellent flow properties (low viscosity) with efficient substrate wetting.

- Unique mechanical properties

APPLICATIONS

- EPX-205 Epoxy is used to potting or encapsulate printed circuit assemblies in a protective block.

- The cured epoxy improves reliability, operational range, and lengthens the life of electrical and electronic parts.

- Its primary applications involve protecting electronic devices in high temperature and chemically aggressive environments in the automobile, marine, aerospace, aviation, communication, instrumentation, and industrial control equipment.

TECHNICAL GUIDELINES FOR USING

- Measure the Part A (Resin ) and the Part B ( Hardener ) in two separate containers.

- Transfer Part A into the suitable container

- Start gentle stirring

- After stirring the Part A, transfer Part B to it.

- Continue the gentle stirring & Reaction to progress.

- Take care not to get air trapped within mixture

- The Mixed epoxy resin should be applied or poured within 5-10 min Time.

- For design applications, Degassing may be required to remove the Air bubbles from the texture.

- Upon curing remove the material from moulds.

STORAGE & PRE-MIXING

- The two components (Resin & hardener) should be stored in separate at all times prior to use.

- Store in cool, Dry & Away from Sun Light.

- Warm Temperature should be avoided in storage area, Warm temperature reduce the shelf life.

- The handling equipment & the storage area should be free from chemical residue, Foreign matters.

SHELF LIFE:

Twelve (12) months from date of shipment when stored at 25oC in the original sealed packages.