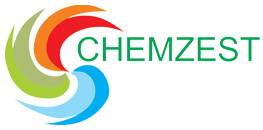

Vacuum degassing is a method for removing dissolved gases from a liquid by lowering the pressure inside a container that has the fluid in it. During the production, the materials can become infused with excess gases, which can lead to imperfections and impact the performance of the casting.

Vacuum degassing systems are used in the process of degassing casting materials such as silicone, resin, gypsum and the process of impregnation of wood and other porous materials.

The vacuum degassing system is operated in the following conditions: ambient temperature between +5°C and +40°C, air humidity up to 80% at 20°C.

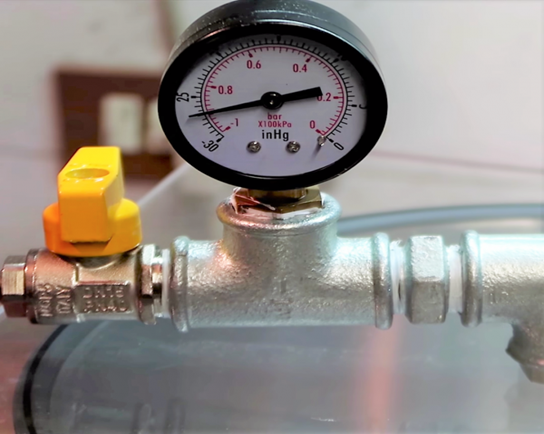

Vacuum degassing system consist of vacuum chamber, vacuum pump, valves and gauges.

A vacuum chamber is a rigid enclosure from which air and other gases are removed by a vacuum pump. This results in a low-pressure environment within the chamber, commonly referred to as a vacuum.

Vacuum Systems (vacuum chambers and vacuum pumps that pull 29 inches of mercury) are used to remove the air from high viscosity materials like silicone rubber,polyurethane resin, Epoxy resin and polyester resin

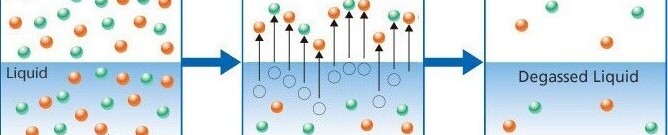

VALVES AND GAUGES

All vacuum chambers are equipped with valves and gauges. Two ballvalves assist in removing air from the chamber to maintain the vacuum and releasing the vacuum.

Gauges are necessary for measuring and displaying vacuum chamber pressure.

The air is sucked out of the resin which causes the bubbles to rise up and then collapse.

This process typically takes a couple of minutes.

NOTE:Resins with short working times should not be vacuum degassed.

VACUUM PUMP

Vacuum pumps essentially move gas molecules from one region to the next to create a vacuum by changing high and low-pressure states. As molecules are removed from the vacuum space, it becomes exponentially harder to remove additional ones, thus increasing the vacuum power required.

Vacuum degassing requires a vacuum chamber. To degas, the mixed resin is placed inside a container and then placed inside the vacuum chamber. The container holding the resin should have enough headspace to accommodate three times the original volume of the resin.

TYPES OF VACUUM CHAMBER

1.BOX VACUUM CHAMBER

Box Chambers can be used for many applications including degassing, atmospheric testing, thin film deposition and space simulation.

Box chamber can be made of stainless steel, Acrylic, Carbon steel.

Box chamber is provided with EPDM/Silicone seal.

| MODEL | B-5 | B-10 | B-20 | B-50 |

| VOLUME(LITRE) | 4.5 | 9 | 18 | 54 |

| CHAMBER SIZE(CM) | L15 X W15 X H20 | L30 X W15 X H20 | L30 X W30 X H20 | L60 X W30 X H30 |

| DOOR TYPE | FRONT OPEN | TOP OPEN | TOP OPEN | TOP OPEN |

| AIR FLOW(CFM) | 2.8 | 4 | 4 | 9 |

| ULTIMATE VACUUM(IN HG) | 29 | 29 | 29 | 29 |

| STAGES | DOUBLE STAGE | DOUBLE STAGE | DOUBLE STAGE | DOUBLE STAGE |

| OIL CAPACITY | 600 | 600 | 600 | 610 |

| POWER | 180W | 350W | 350W | 750W |

| DIMENSION(CM) | 35 X 14 X 25 | 35 X 14 X 25 | 35 X 14 X 25 | 38 X 16 X 29 |

| WEIGHT(KGS) | 10 | 10.5 | 10.5 | 15 |

2.ROUND VACUUM CHAMBER

Round vacuum chamber is more effective and compactable for the resin degassing systems, which occupy less foot print and easily movable. Its energy efficiency less compared to box type chamber

Vacuum Degassing Systems Processes

1.Degassing liquid

2.Degassing polyurethane resin

3.Degassing silicone

4.Degassing epoxy resin

| MODEL | R-5 | R-10 | R-20 | R-50 |

| VOLUME(LITRE) | 5 | 10 | 20 | 50 |

| CHAMBER SIZE(CM) | DIA 16 X HT 23 | DIA 20 X HT 20 | DIA 30 X HT 30 | DIA 40 X HT 40 |

| DOOR TYPE | TOP OPEN | TOP OPEN | TOP OPEN | TOP OPEN |

| AIR FLOW(CFM) | 2.8 | 4 | 4 | 9 |

| ULTIMATE VACUUM(IN HG) | 29 | 29 | 29 | 29 |

| STAGES | DOUBLE STAGE | DOUBLE STAGE | DOUBLE STAGE | DOUBLE STAGE |

| OIL CAPACITY | 600 | 600 | 600 | 610 |

| POWER | 180W | 350W | 350W | 750W |

| DIMENSION(CM) | 35 X 14 X 25 | 35 X 14 X 25 | 35 X 14 X 25 | 38 X 16 X 29 |

| WEIGHT(KGS) | 10 | 10.5 | 10.5 | 15 |

CATLOG